Other eCommerce industries have it easy when it comes to shipping, but not the parts department. There are so many heavy, oversized, odd-shaped, and hazardous auto parts to ship that it ends up one of the biggest expenses when selling online.

You certainly can’t eat that shipping charge yourself, since it will cut into your hard-earned profits. And you shouldn’t be overcharging your customers for shipping, either. If you could make shipping just overall cheaper, then everyone would win…

Even if you have the customer pay the shipping charge, you should still be paying attention. Seriously—cheaper shipping overall helps everyone. Shipping charges are one of the top reasons for a customer to abandon their purchase, so you’ll cost yourself sales if you’re not careful.

Don’t overpay for shipping. Don’t make your customer overpay for shipping. Save everyone some money by following these tips:

1. Look into shipping managers.

If you’re selling over 50k a month in online parts sales, it’s time to consider getting a shipping manager. It’ll save you a ton of time by handling all the dirty details, and time is money when it comes to business. A shipping manager will usually pay for itself in the first month.

The biggest plus of shipping management software: time and labor costs. All of your order details—even across multiple channels—are available in one spot, and most of it can be automated. In addition, most shipping managers also make it easy to comparison shop for the best shipping price. You can even run reports to help you optimize the entire process.

Just make sure the software integrates with your parts eCommerce solution before you purcahse it. Shipping managers almost always offer a free trial, so try it out!

PS: RevolutionParts integrates with ShipStation, ShipWorks, and ShipRush Web. We also have a simple shipping manager built into the RevolutionParts platform, allowing you to print shipping labels straight from the order form.

2. Narrow your focus.

With so many shipping carriers out there (USPS, UPS, and FedEx, among others), you really can fight to find the cheapest price. But usually the difference between carriers is only a few dollars, so while it helps, it’s not a life changing difference.

Typically, you’re better off sticking to 1 or 2 carriers. We recommend USPS + one other of your choice. Using two shipping carriers removes a lot of complication from your fulfillment process, and usually you can quality for volume discounts.

You might be able to negotiate for better rates by calling their 800 number. Even if you think your parts store is too small, you won’t know for sure until you try!

3. List options as “standard” on your parts website.

You don’t need to specify which carrier you plan on using on the order page. Most customers don’t care whether their part comes through USPS, UPS, or FedEx—it’s all the same to them, as long as their parts arrive undamaged and in a timely manner.

When listing the shipping options, keep it generic. Offer options like “standard ground shipping”, “standard 2-day”, “standard overnight”, and so on. This way you’re not locked into shipping with a specific carrier. After the order is placed, YOU can choose to ship with the carrier that offers the best price.

4. Double check weight and dimensions.

How many thousands of parts are listed in your online catalog? We strive for accuracy, but sometimes data is missing. It only takes a second to glance at the weight and dimension information before you send the order through. Incorrect calculations won’t end well for anyone!

Most successful dealers on the RevolutionParts platform tell us that double checking the catalog info is part of their shipping process. The employee taking care of shipping for the day will ALWAYS check and update the catalog info if necessary. It’s especially worth the added seconds because once you update the RevolutionParts catalog, incorrect W&D for that part won’t ever bother you again.

5. Have a variety of box sizes available.

If you’re shipping a tiny spark plug in a huge 2-foot box, you’re doing something wrong. The box you use for packaging should be as close to the part size as possible.

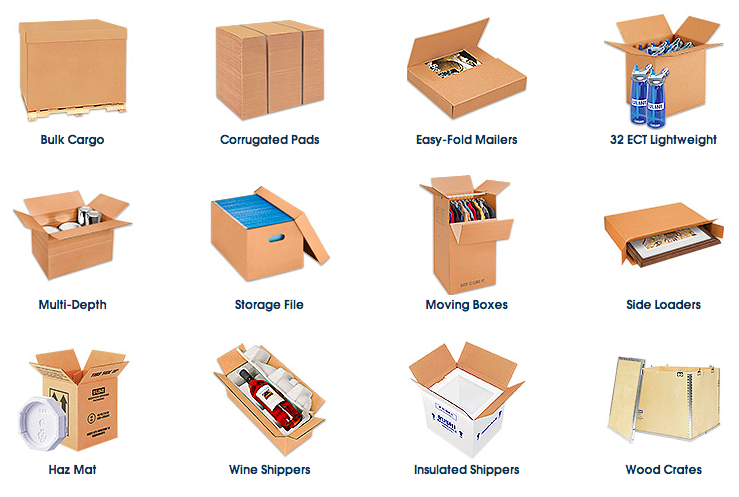

Dimensions can make a huge difference when it comes to paying for shipping. It’s worth having a variety of box sizes on hand. The more you sell online, the more you’ll get an idea for which boxes sizes you use the most. This saves you money, but it also protects your part. You don’t want anything rattling around during shipment!

Sometimes you can even get boxes free of charge! Through UPS and USPS, certain boxes are free and you only pay for the shipping itself. Granted, they tend to be on the smaller size so you can’t use the free boxes for everything. But it can still make a difference!

6. Don’t overpay for packing materials.

Don’t buy retail when it comes to boxes and packing materials—buy straight from a manufacturer. When you purchase in bulk, you can save yourself a lot on packaging. Boxes can be as low as $0.79 each, depending on the size you choose.

Whether you buy online or drive to your nearest manufacturer, you can save a lot of money when boxes are less than a dollar each.

ShippingSupply.com offers a ton of options for any shipping needs you have. They have countless box size options, hazardous material boxes, bubble wrap, tape, and more.

7. Use the original box for shipping, in certain cases.

Sometimes the original manufacturer box works just fine for shipment, which saves you the trouble and cost of repackaging it. Wrap it in Kraft paper or ship it as-is. This doesn’t just save time. It also reduces the overall time your team spends on shipping!

This technique doesn’t work for everything. Expensive and fragile parts should be repackaged for the extra padding, so they aren’t damaged during shipment.

8. Don’t skimp out when you need to.

For expensive and fragile items, make sure everything is properly packaged. Use enough packing peanuts, bubble wrap, or whatever else you prefer to ensure that the product arrives safely.

In fact, it’s usually best to overuse packing materials. Even though it’ll be an additional upfront cost to use more bubble wrap than necessary, it’s worth your investment. If the auto part arrives to the customer damaged, you will be held responsible. The added safety of bubble wrap or packing peanuts will protect you against the huge loss of a returned order and a damaged product.

At the end of the day, shipping prices are going to add some complication to the selling process, and you won’t always get the cheapest option. But these practices will become habit and then saving money on shipping will be second nature.